Supply Chain Digital Twin

“A (supply chain) digital twin is a virtual supply chain replica that represents hundreds of assets, warehouses, logistics and material flows, and inventory positions. Using advanced analytics and artificial intelligence (AI), the digital twin simulates the supply chain’s performance, including all the complexity that drives value loss and risks. It identifies where volatility and uncertainty exist, as well as where optimization is possible.”

Boston Consulting Group

What we do

Developed by supply chain experts and academics to address short comings in existing solutions, SupplyVue Navigate provides digital twin optimisation through:

Built on a cloud-based technology platform, SupplyVue Navigate uses the latest version of Azure to ensure the software is fully interactive, scalable and of enterprise quality.

SupplyVue Solver is a multi-objective function optimisation (i.e. service, cost, carbon) solution that determines the policies and parameters to optimally balance costs, carbon emissions and service across the supply chain.

Supply chain synchronisation assessment. Revealing time, cost and carbon build-up through the network. Show where process hand-offs are causing value loss. Model and evaluate synchronisation benefits.

SupplyVue Network Planner is a multi-echelon network planning solution. It propagates demand through the network, aligned to a repetitive supply cycle rhythm, resulting in a predictable, stable demand drumbeat that synchronises activities across the supply chain.

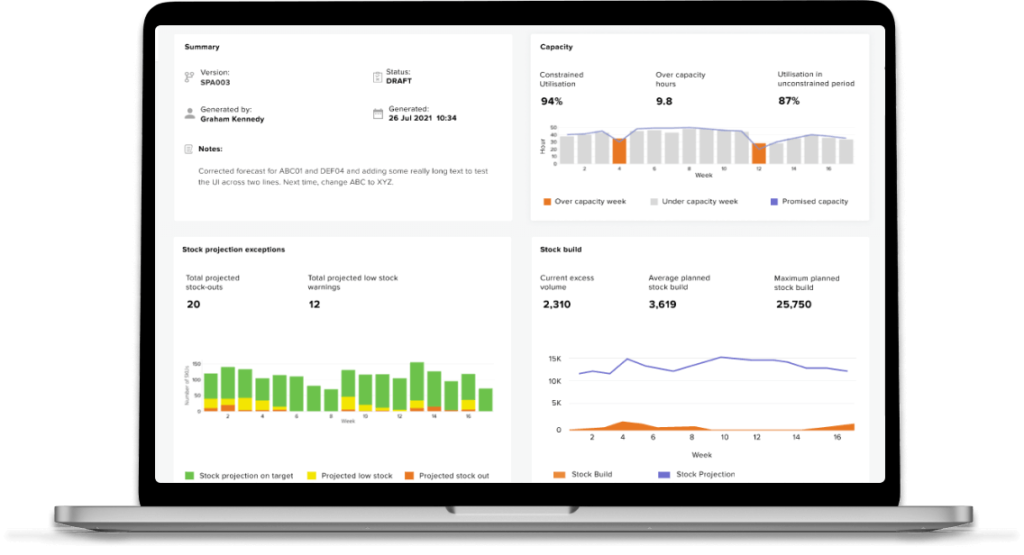

Our platform builds a data model that replicates your supply chain and is ready to use for analytics, modelling, and simulation.

Creates a digital replica of your supply chain that provides a single repository that spans the whole organisation and supports self-service analytics. Structured to ensure visibility through multiple perspectives and at different hierarchy levels (e.g. demand segments, source site mapping, etc.) and to enable ‘drill down’ to transaction level detail for root cause analysis.

Assesses your supply chain with clearly defined, consistent metrics focussed on process excellence, not just business outcomes. Allowing you to view and benchmark performance across the organisation in a consistent and objective fashion and to target improvement projects that support integration of the supply chain and deliver efficiencies and cost reductions.

Generates a production plan template to drive economies of repetitions in supply chain execution, by calculating fixed production cycles to improve plan stability for manufacturing AND provide more predictable and reliable supply for inventory management and customer service. Generic algorithms calculate optimal settings for overall supply chain cost and/or carbon minimisation goals for the supply chain.

Tests supply chain design through what-if scenario modelling, sensitivity analysis and simulation. Run end to end simulation to test the policies and tune the settings. Run What-if modelling scenarios to support Network risk management and business tactical planning. Evaluate investment options, resource level changes and find opportunities to make the supply chain more efficient and effective.

Get started