Embedded expertise, powered by AI

Expert level planning, delivered simply.

SupplyVue solutions combine domain-specific AI with supply chain best-practice to create expert systems that simplify complex supply chain problems to deliver smart and transparent solutions.

At SupplyVue, we’ve distilled years of supply chain expertise into cutting-edge solutions to create supply chain expert systems. By using SupplyVue your business gains this expertise – without the need for extra staff or costly system upgrades.

SupplyVue Planning Copilot

Your Planning Copilot for Next-Level Supply Chain Performance

SupplyVue Planning Copilot is an AI adviser that plugs into your planning solutions – optimising flows and driving efficiency.

It analyses your supply chain performance, assesses the profiles of each SKU and recommends optimal planning parameters settings.

Key features

- Cleanses and enriches data for accurate, high-fidelity modelling

- Optimises production frequencies, lot sizes, and planning system parameters

- Dynamically adjusts parameters as the context changes

- Simulates process execution adding buffers to create resilience

Complex factories, multi-site networks, and variable constraints – simplified, synchronised, and optimised.

Unlocking more value from your current tools with AI-driven precision

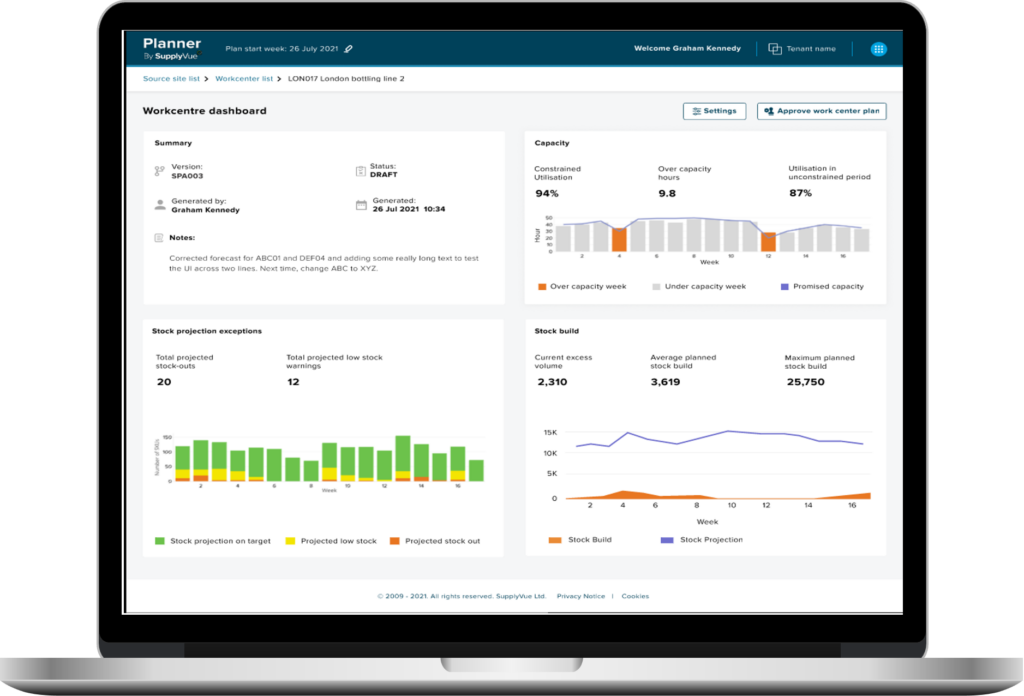

SupplyVue Network Planner

Self-correcting autonomous planning

SupplyVue Network Planner makes factory and network planning simple, visual, and actionable. It incorporates decades of supply chain expertise, so users don’t have to be experts to get expert-level results. We’ve done the hard thinking so your team can focus on execution, not wrestling with algorithms.

Key features

- Plan solving respecting production wheels and batch grouping

- Multi-stage planning and constraining

- In-bound material constraining

- Dual sourcing and alternative workcentre plan resolution

- Automated Bow-wave correction

- Rule based final plan resolution

SupplyVue Network Planner is easy-to-implement, simple-to-use, and a highly functional solution.

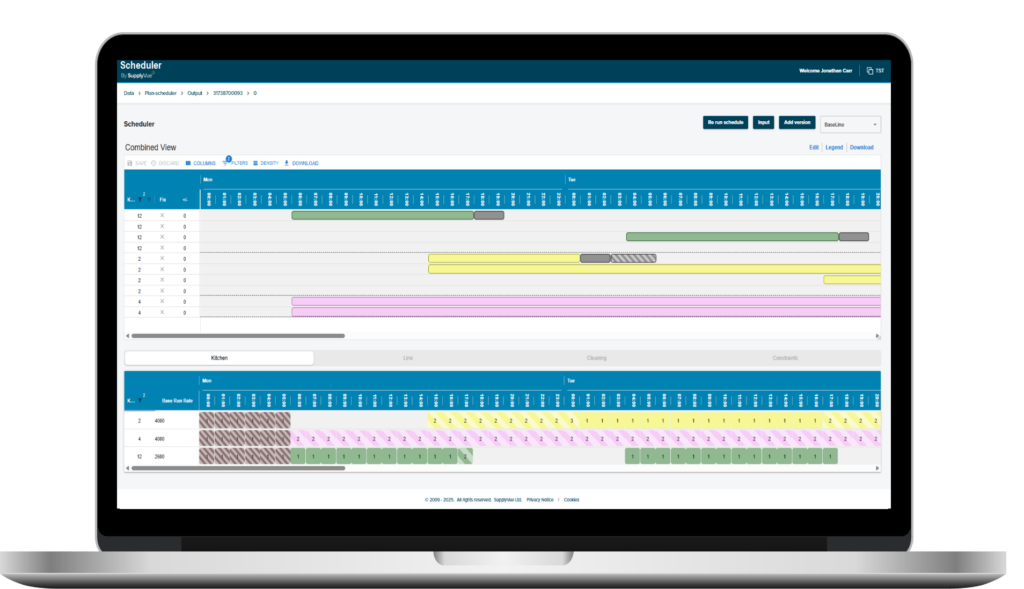

SupplyVue Advanced Scheduler

Advanced scheduling capability, using AI and ‘the human in the loop’ to solve complex scheduling problems

Key features

- Optimal production wheel design for each workcentre

- Integrated planning and scheduling across the operational time horizon

- Cross factory shopfloor synchronisation, considering cross workcentre resource planning and restrictions

- In week re-scheduling based on Lean Manufacturing best practice principles of least disruption

- Full digital twin capability providing resource, routing, and portfolio optimisation and simulation

SupplyVue Advanced Scheduler is a synergy between human expertise and AI precision to deliver the strongest results